2023-01-30

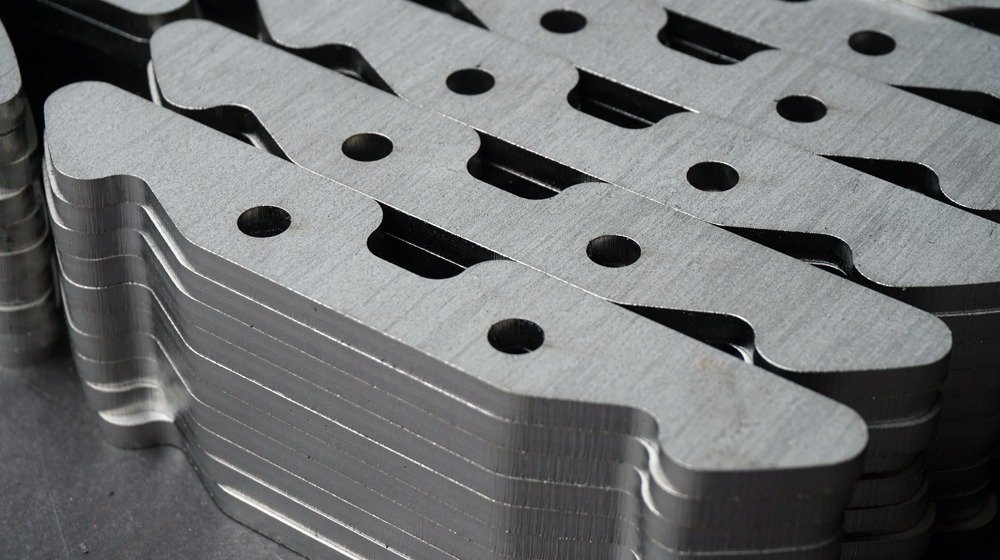

Fiber laser cutting machine have become an innovation for companies in the metal machinery industry that require steel cutting and seek to improve quality while increasing yield, enabling greater precision and speed in cutting and engraving.

1. Working principle: The light beam (laser) generated by the pump diode passes through the optical fiber with rare earth elements, which are a special chemical element. The laser is capable of cutting metals of different types, thicknesses and speeds

So, at Tigertec, we have the machines and consumables to meet your production needs, so you can get the most out of your consumables and operating time. We can share with you which is the best option so you can update or innovate in your business.

2. Good stability The beam passes through the fiber optic cable, providing greater stability.

3. High Precision Fiber provides higher cutting precision, because the beam only passes through the core of the fiber, the diameter is reduced, it achieves higher precision by being straighter and concentrating the beam at a smaller cutting point.

4. Reduce cost and power consumption Fiber lasers manage to convert 25% to 30% of the energy they consume into useful cutting power, thus minimizing environmental impact and reducing power consumption.

5. Training is simple and easy to operate No professional technicians are required, one person is enough to operate this type of equipment.

What materials can the laser cut?

Carbon Steel, Stainless Steel, Aluminum, Brass, Copper, Titanium, Silver

More

News

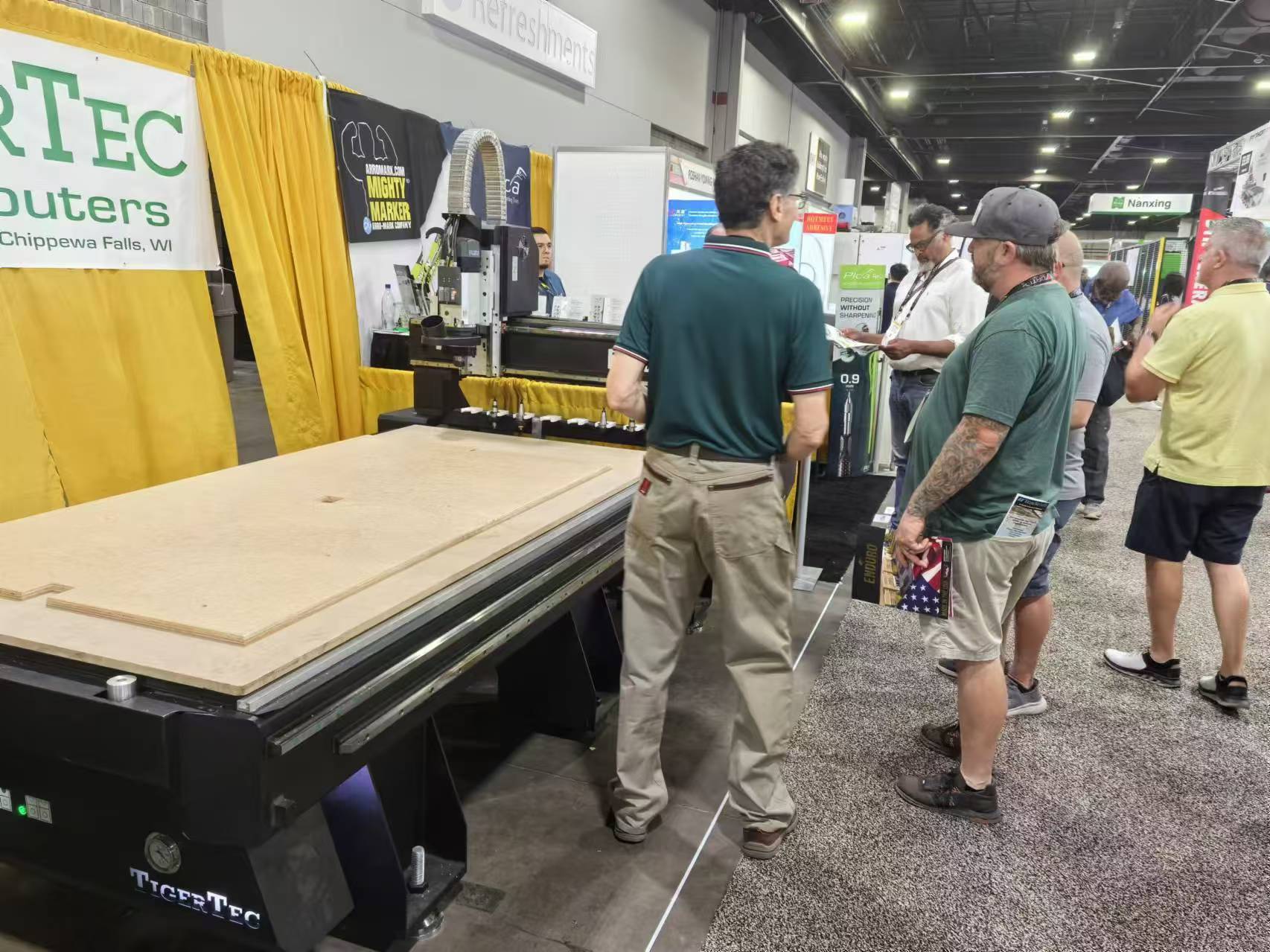

IWF ATLANTA 2024

2024-06-25

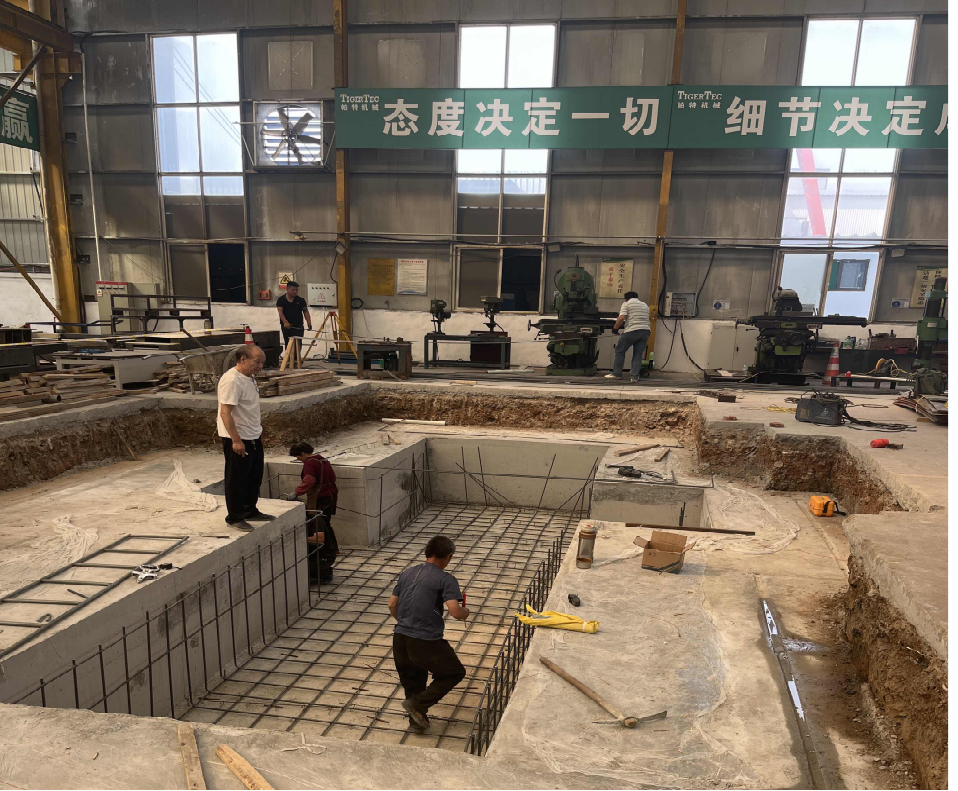

Another Machining Center

2024-05-27