Heavy duty welded steel structure guarantees solidity and absence of vibration, for consistent product quality over time.

T-slot solid Aluminum table with T-Nuts and Clamps included.

Absolute Servo with high precision Planetary Reducer on all axis.

High power motorized spindle can easily process all kinds of materials

PT 2030 selects Italian HSD air-cooled spindle ES951 9.5KW. Choose from manual, quick-release, high-power and high-speed spindles for optimum processing of rigid sheet materials.

Quality power reliability precision, available with 9.5kw-18kw Automatic Toolchange Spindle.

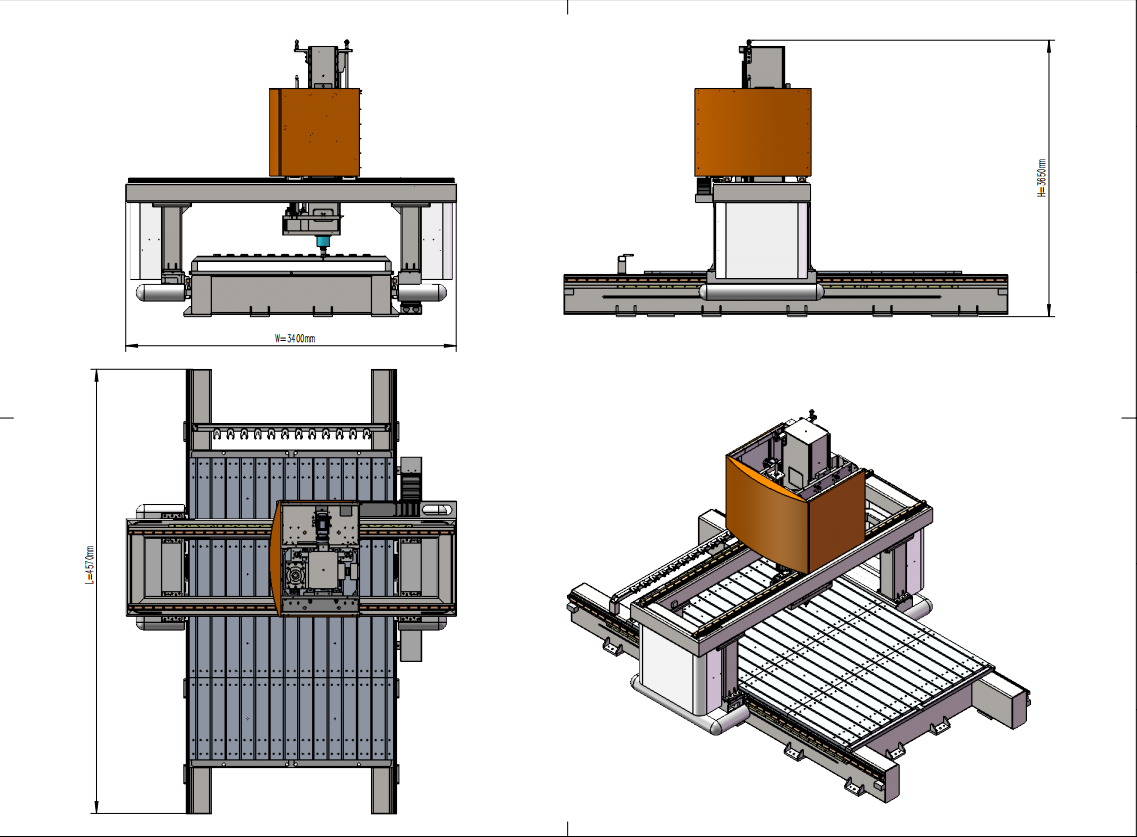

TigerTec PT710 is designed with flexibility in mind and you can use this model for any CNC project in foundry industry. We use more stronger parts for the whole machine to ensure you can get higher accuracy and speed, but with an affordable price. We also offer some options for this machines, different power of spindles, motors and special size as request.

Outstanding features:

*High precision and reliability over time.

*High Speed absolute Servo Drives on all axes.

*Rack and Pinon on X and Y using Planetary Gear Boxes, Ball Screw on Z-axis

*Installation of linear rail for XY-axes is designed to increase precision and reliability standards for the execution of machining operations.

*Wide range of table sizes available covers all the standard panels size in the nesting industry and customers can choose the most suitable machine for their needs.

Applications:

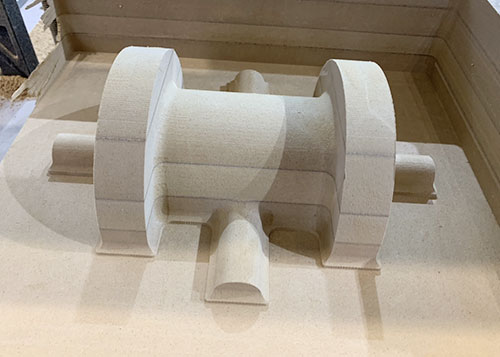

Solid wood, styrofoam, wax, plaster of paris, aluminum and foam patterns are well suited for high speed milling. 3-axis CNC machines is particularly suitable for automotive foam mold, Value body industries wooden ship model, wooden model aviation, trains and other wooden mold. This size allows us to minimize setup times and cut patterns larger than the industry norm.

Model No: | PT510/PT710/PT712 |

Working area(X-Y): | 1500*3000mm, 2000*3000mm,2000*4000mm |

Working area (Z-axis): | 400/600/900mm |

Travelling Speed: | 30m/min (X-Y), 15m/min (Z-axis) |

Spindle Motor: | 9.5-18KW, HSD, 3000-24000RPM7.0KW Milling Spindle, 6000-12000RPM |

Power Input: | 380V,3PH,50/60HZ |

Tool holder: | IS030/HSK63F/BT40 |

Magazine No: | 8-16 pcs |

Controller: | SIEMENS/SYNTEC |

Driving System: | Absolute Servo with high precision Planetary reducer |

Transmission X, Y & Z: | Helical WMH herion of Germany,HIWIN linear rail |

File transfer Mode: | TCP/IP or USB |

CNC - Nesting machining centre is the new high-performance machining centre for Nesting operations, compact and efficient, with a gantry structure, TigerTec offers top-of-the-range technology and guarantees optimum precision in every machining operation.

EXPLOPE

Hydraulic Bending Machine is a type of sheet metal bending machine, which is suitable for sheet metal plate bending process. The press brake capacity ranges from 40 ton to 400 ton and the table length from 2 meters to 6 meters. Hydraulic Bending Machine belongs to forging machineries. The main role is in the metal processing industry. Then, its products are widely used in light industry, aviation, shipbuilding, metallurgy, instrument, electrical appliances, stainless steel products, steel structure construction and other industries.

EXPLOPE

TigerTec TR408AD ATC is designed for efficient working in speed and reliability.

EXPLOPE

TigerTec Inc is a manufacturer of CNC routers, CNC plasma cutters, CNC laser cutters, CNC assessories, Fiber laser cutting machine and handheld fiber laser welding machine and so on.

Address: #6 Caofan Industrial Park, Zhangqiu Dist. Jinan, Shandong P.R. China E-Mail: info@tigerteccnc.com.cn Phone: +86 13335116636 Tech Support: support@tigerteccnc.com.cn Phone: +86 18560168108

TIGERTEC US

Address: #1406 Lowater R.d, Chippewa Falls, WI 54729, USA

E-Mail: david_slowinski@hotmail.com Phone: +1 (715) 456-1919

Phone: 0086-67800878-8000 Fax: 0086-67800878-8029 info@tigerteccnc.com.cn 【I also want to customize a website】