Working size: 1240x2460mm, 3 tons as standard. Optional: 1830x3650mm, 4tons / 2100x4050mm, 4tons. Loading table could automatically rise to the correct height and at the correct time by the function of automatic light spot switch whenever the machine automatically grab panel plate.

The finished work pieces would be automatically moved to the Conveyor to save the time.The operator can pick up the work pieces and move to the edge banding machine.

With the ability labels on the router table before nesting has helped boost panel processing capability. Easy to assemble when the cabinet arrived to the end user's place according to the blue print.

HSD 5+4 boring units as standard configuration. Boring units are available in a wide range of versions for your choice.

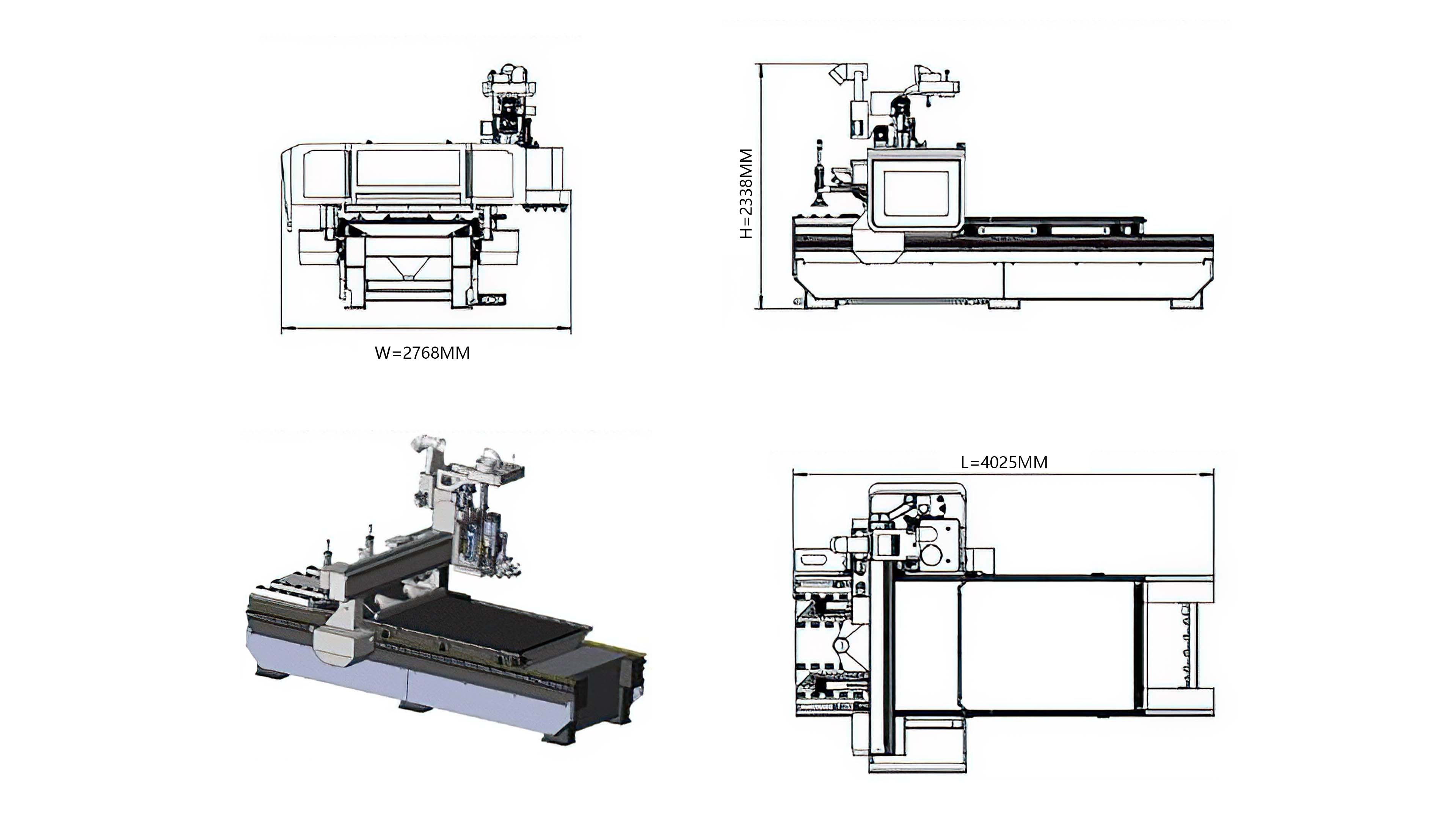

CNC machining center routing nesting drilling is the gantry machining center with robust, well-balanced structure, designed for nesting applications of wood and wood based materials, but also plastic based and non ferrous materials machining to handle demanding machining requirements without compromising product quality by quick and reliable delivery times.

Outstanding Features:

* High precision and reliablity over time

* High processing flexibility

* Maximum productivity, minimum footprint

* Full production at a competitive price

* Machine customization depending on different production requirements

Appications:

Wooden door, kitchen cabinet, wine cabinet, game cabinet, panel furniture, office furniture, closet, customized furniture, table, chair, voice box, cupboard door, stereo wave board, ets. Suitable for standard or bespoke production.

Model No. | Process Area | Accuracy | Weight | Foot Print | ||||

X | Y | Z | W | L | H | |||

TZ408-12-9A | 1240mm | 2460mm | 200mm | ±0.05mm | 3500KGS | 2768mm | 4025mm | 2300mm |

51.2″ | 98.4″ | 7.9″ | 109″ | 158.5″ | 91″ | |||

TZ612-12-9B | 1830mm | 3050mm | 200mm | ±0.05mm | 4500KGS | 3770mm | 5350mm | 2300mm |

70.9″ | 141.8″ | 7.9″ | 150″ | 210″ | 91″ | |||

CNC - Nesting machining centre is the new high-performance machining centre for Nesting operations, compact and efficient, with a gantry structure, TigerTec offers top-of-the-range technology and guarantees optimum precision in every machining operation.

EXPLOPE

Hydraulic Bending Machine is a type of sheet metal bending machine, which is suitable for sheet metal plate bending process. The press brake capacity ranges from 40 ton to 400 ton and the table length from 2 meters to 6 meters. Hydraulic Bending Machine belongs to forging machineries. The main role is in the metal processing industry. Then, its products are widely used in light industry, aviation, shipbuilding, metallurgy, instrument, electrical appliances, stainless steel products, steel structure construction and other industries.

EXPLOPE

TigerTec TR408AD ATC is designed for efficient working in speed and reliability.

EXPLOPE

TigerTec Inc is a manufacturer of CNC routers, CNC plasma cutters, CNC laser cutters, CNC assessories, Fiber laser cutting machine and handheld fiber laser welding machine and so on.

Address: #6 Caofan Industrial Park, Zhangqiu Dist. Jinan, Shandong P.R. China E-Mail: info@tigerteccnc.com.cn Phone: +86 13335116636 Tech Support: support@tigerteccnc.com.cn Phone: +86 18560168108

TIGERTEC US

Address: #1406 Lowater R.d, Chippewa Falls, WI 54729, USA

E-Mail: david_slowinski@hotmail.com Phone: +1 (715) 456-1919

Phone: 0086-67800878-8000 Fax: 0086-67800878-8029 info@tigerteccnc.com.cn 【I also want to customize a website】