Be easily customized to fit your particular part geometry. Simplest and fastest way to hold down your sheet goods.

Multi-heads can realize the automatic tool change function. An economic and practical ATC machine for your choice.

Easy-to-use hand held controller: Separated design, protect control parsing module to the largest extent ; Arc machining, faster and rounder ; Support multi-language, switch between metric and inch ; Breakpoint resume.

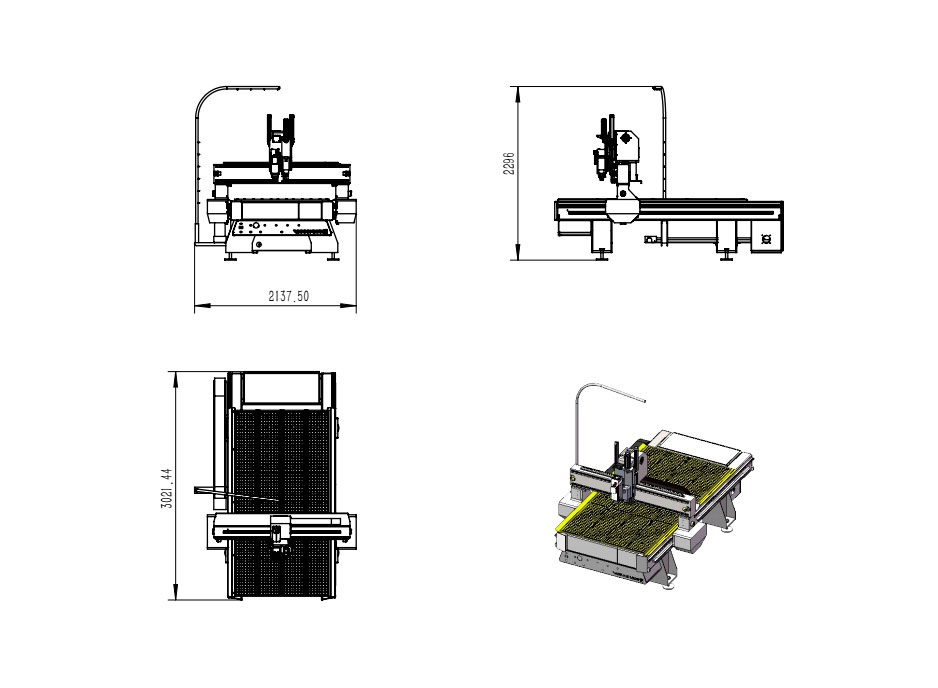

Heavy-duty lathe bed, adopt thick steel tube with thickness of 5mm, 7 beams in line in the lathe bed, equal-distance long welding spot and 12 hours’ heat treatment, which could ensure the working table more stable without deformation when machine move so as to keep higher accuracy work by faster speed. Adding the steel belt on the surface of the table, which are milled by our own machining center, it can maximum ensure table flat and firm so that machine can work with high precision.

TR408AD with dual spindles is an economical and practical model, two spindles, the bigger one for cutting, the smaller one for grooving or drilling, saving time for changing different tools.

Outstanding features:

* an economical and practical model, two spindles, the bigger one -7.0kw Italy HSD for cutting, the smaller one -1.5kw Italy HSD for grooving or drilling, saving time for changing different tools.

* Italian HSD air-cooled spindle with electric fan, powerful and quite.

* Makes your industries high-tech at an affordable cost with DSP off-line control system useful for high speed and accurate cutting in furniture & door industries.

Applications:

An TigerTec CNC router will.

Eradicate the need for outsourcing, saving time and money.

Improve turnaround with TigerTec products offering up to 70% faster production capabilities than manual processes.

Improve bottom line, reduce human error and material wastage by up to 30% by getting it right on the first pass.

Model No. | Process Area | Accuracy | Weight | Power of dual spindles | ||

X | Y | Z | ||||

TR408AD With dual spindles | 1300mm | 2500mm | 200mm | + 0.05mm | 1400KGS | • 7.0Kw Italy HSD air cooling spindle, ER32, 18000rpm

• 1.5Kw Italy HSD air cooling spindle, ER25, 18000rpm |

51.2″ | 98.4″ | 7.9″ | ||||

TR510AD With dual spindles | 1500mm | 3000mm | 200mm | + 0.05mm | 1700KGS | |

59.0″ | 118.1″ | 7.9″ | ||||

TR710AD With dual spindles | 2000mm | 3000mm | 200mm | + 0.05mm | 2000KGS | |

78.7″ | 118.1″ | 7.9″ | ||||

TR712AD With dual spindles | 2000mm | 4000mm | 200mm | + 0.05mm | 2200KGS | |

78.7″ | 157.5″ | 7.9″ | ||||

CNC - Nesting machining centre is the new high-performance machining centre for Nesting operations, compact and efficient, with a gantry structure, TigerTec offers top-of-the-range technology and guarantees optimum precision in every machining operation.

EXPLOPE

Hydraulic Bending Machine is a type of sheet metal bending machine, which is suitable for sheet metal plate bending process. The press brake capacity ranges from 40 ton to 400 ton and the table length from 2 meters to 6 meters. Hydraulic Bending Machine belongs to forging machineries. The main role is in the metal processing industry. Then, its products are widely used in light industry, aviation, shipbuilding, metallurgy, instrument, electrical appliances, stainless steel products, steel structure construction and other industries.

EXPLOPE

TigerTec TR408AD ATC is designed for efficient working in speed and reliability.

EXPLOPE

TigerTec Inc is a manufacturer of CNC routers, CNC plasma cutters, CNC laser cutters, CNC assessories, Fiber laser cutting machine and handheld fiber laser welding machine and so on.

Address: #6 Caofan Industrial Park, Zhangqiu Dist. Jinan, Shandong P.R. China E-Mail: info@tigerteccnc.com.cn Phone: +86 13335116636 Tech Support: support@tigerteccnc.com.cn Phone: +86 18560168108

TIGERTEC US

Address: #1406 Lowater R.d, Chippewa Falls, WI 54729, USA

E-Mail: david_slowinski@hotmail.com Phone: +1 (715) 456-1919

Phone: 0086-67800878-8000 Fax: 0086-67800878-8029 info@tigerteccnc.com.cn 【I also want to customize a website】