Easy-to-use hand held controller: Separated design, protect control parsing module to the largest extent ; Arc machining, faster and rounder ; Support multi-language, switch between metric and inch ; Breakpoint resume.

Machining center to work on the table, gantry and other big parts for CNC routers. With the help of the big machine, we get better accuracy and good finishing.

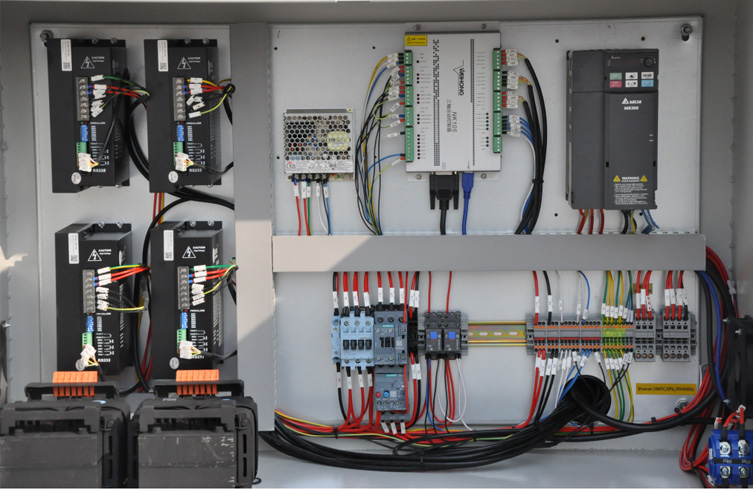

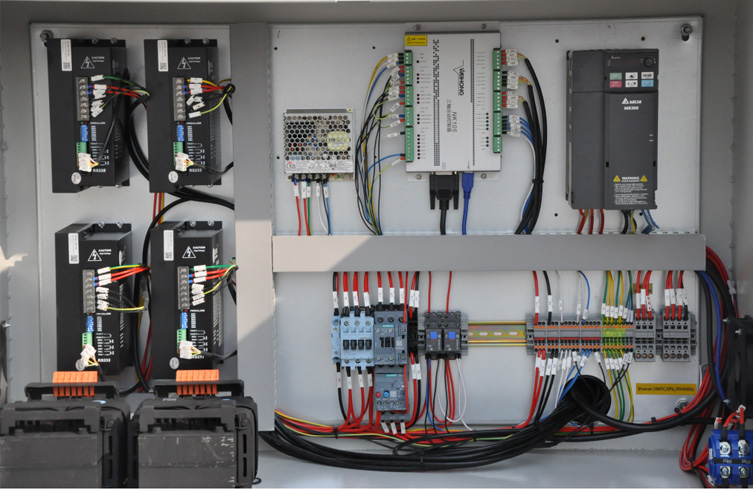

The control cabinet is placed behind the machine to effectively reduce the floor area We use electrical accessory like Siemens and Schneider and Phoenix to ensure the long service life of the machine.

Be easily customized to fit your particular part geometry. Simplest and fastest way to hold down your sheet goods.

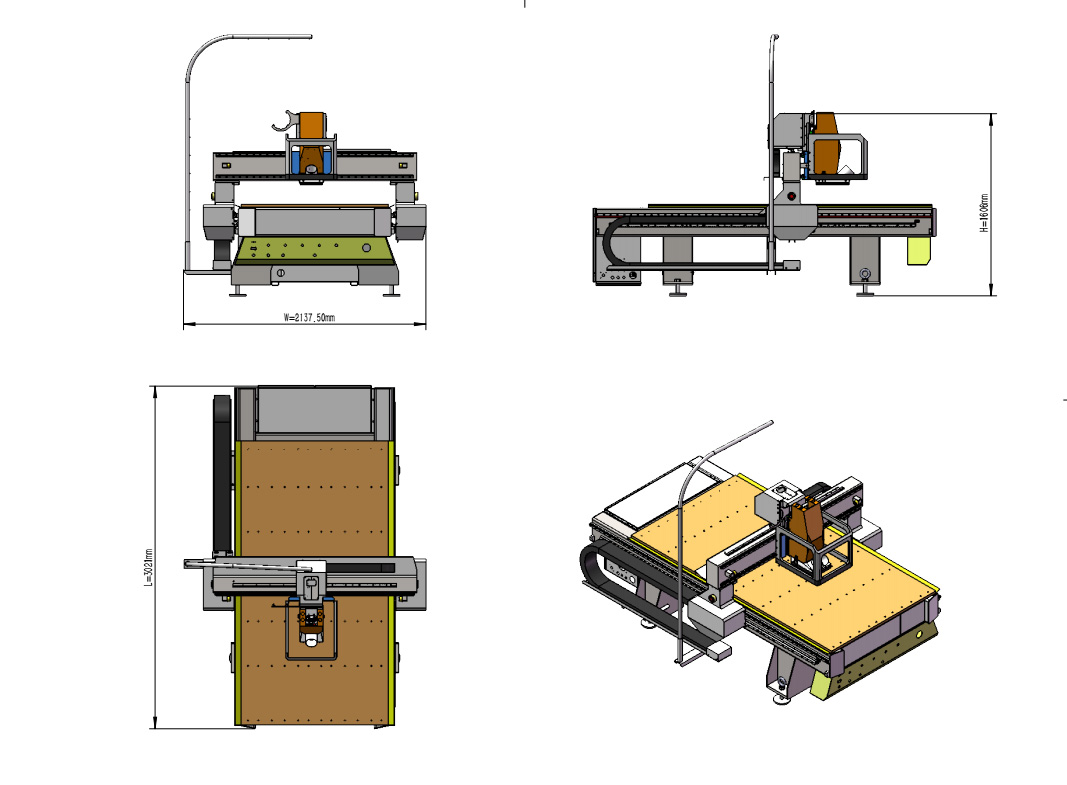

TR408AD Using strong lathe bed, gantry and gantry support for this machine to guarantee the accuracy. All the mechaical parts are done by VMC in our factory.

Industrial steel pipe frame, with stable moving, low noise and high precision.

features a heavy, all-steel tube frame that ensures durability. It also makes your CNC machine more rigid, which reduces vibration and improves routing quality. A three-axis motion control system gives you tight control over routing quality for precision and quality cutting your customers will love.

Outstanding Features:

* 1240*2460mm (4′ x 8′ ) process area

* Mechanical parts: All mechanical parts made in TigerTec factory by CNC machine tools to ensure we have better quality.

* Electronics: We use all world branded components for TigerTec CNC routers, as: Siemens, Schneider, Igus and Phoenix

* Electronic spindle: We use HSD 3.0KW from Italy which is the top brand in the world.

* Painting: We use sand blasting and powder coating for the machine.

* DSP controller with USB connection, a magnetic hand held manual controller ( Extremely Easy Functions )

* Massive gantry rides on extremely accurate TigerTec rack and pinion and HIWIN linear guide ways for each of XYZ -movements

* Powered by Stepper driving system with planetary reducer

* Work surface constructed bakelite with T-slot tracks ensure plenty of options for holding down materials.

Applications:

Widely applied in Sign Making, Musical Instrument, Woodworking, Plastics, Foam, Prototyping, Model making, Education, General Fabrication, Furniture making and Craft making.

Model No. | Process Area | Accuracy | Weight | Foot Print (W*L*H) | ||||

X | Y | Z | ||||||

TR408AD

| 1240mm | 2460mm | 200mm | + 0.05mm | 1200KGS | 2024mm | 3300mm | 1600mm |

51.2″ | 98.4″ | 7.9″ | 79.7″ | 129.9″ | 63″ | |||

TR510AD | 1500mm | 3000mm | 200mm | + 0.05mm | 1500KGS | 2224mm | 3800mm | 1600mm |

59.0″ | 118.1″ | 7.9″ | 87.6″ | 149.6″ | 63″ | |||

TR710AD | 2000mm | 3000mm | 200mm | + 0.05mm | 1800KGS | 2724mm | 3800mm | 1600mm |

78.7″ | 118.1″ | 7.9″ | 107.2″ | 149.6″ | 63″ | |||

TR712AD | 2000mm | 4000mm | 200mm | + 0.05mm | 2000KGS | 2724mm | 4800mm | 1600mm |

78.7″ | 157.5″ | 7.9″ | 107.2″ | 189″ | 63″ | |||

CNC - Nesting machining centre is the new high-performance machining centre for Nesting operations, compact and efficient, with a gantry structure, TigerTec offers top-of-the-range technology and guarantees optimum precision in every machining operation.

EXPLOPE

Hydraulic Bending Machine is a type of sheet metal bending machine, which is suitable for sheet metal plate bending process. The press brake capacity ranges from 40 ton to 400 ton and the table length from 2 meters to 6 meters. Hydraulic Bending Machine belongs to forging machineries. The main role is in the metal processing industry. Then, its products are widely used in light industry, aviation, shipbuilding, metallurgy, instrument, electrical appliances, stainless steel products, steel structure construction and other industries.

EXPLOPE

TigerTec TR408AD ATC is designed for efficient working in speed and reliability.

EXPLOPE

TigerTec Inc is a manufacturer of CNC routers, CNC plasma cutters, CNC laser cutters, CNC assessories, Fiber laser cutting machine and handheld fiber laser welding machine and so on.

Address: #6 Caofan Industrial Park, Zhangqiu Dist. Jinan, Shandong P.R. China E-Mail: info@tigerteccnc.com.cn Phone: +86 13335116636 Tech Support: support@tigerteccnc.com.cn Phone: +86 18560168108

TIGERTEC US

Address: #1406 Lowater R.d, Chippewa Falls, WI 54729, USA

E-Mail: david_slowinski@hotmail.com Phone: +1 (715) 456-1919

Phone: 0086-67800878-8000 Fax: 0086-67800878-8029 info@tigerteccnc.com.cn 【I also want to customize a website】