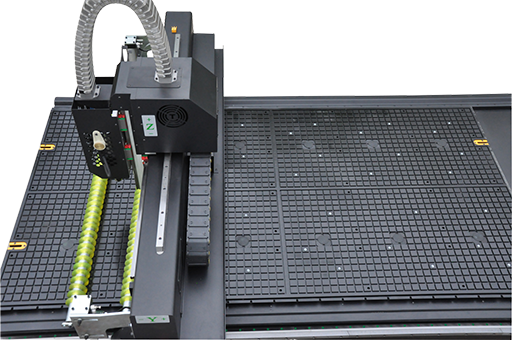

The table can be zoned by easily moving gasket around to customize specific sections. Gasketing can also be routed to accommodate various material sizes and styles.

The gantry is constructed of tubular steel with reinforcing ribs.This quality engineering and workmanship result in smooth precision cutting.

Including precision rack and pinion drive, the heavy duty fully enclosed energy chain prevents ingress of chips and dust reducing wear.

Siemens contactors with a robust and reliable, fraceable, numbered wiring scheme give you long term peace of mind.

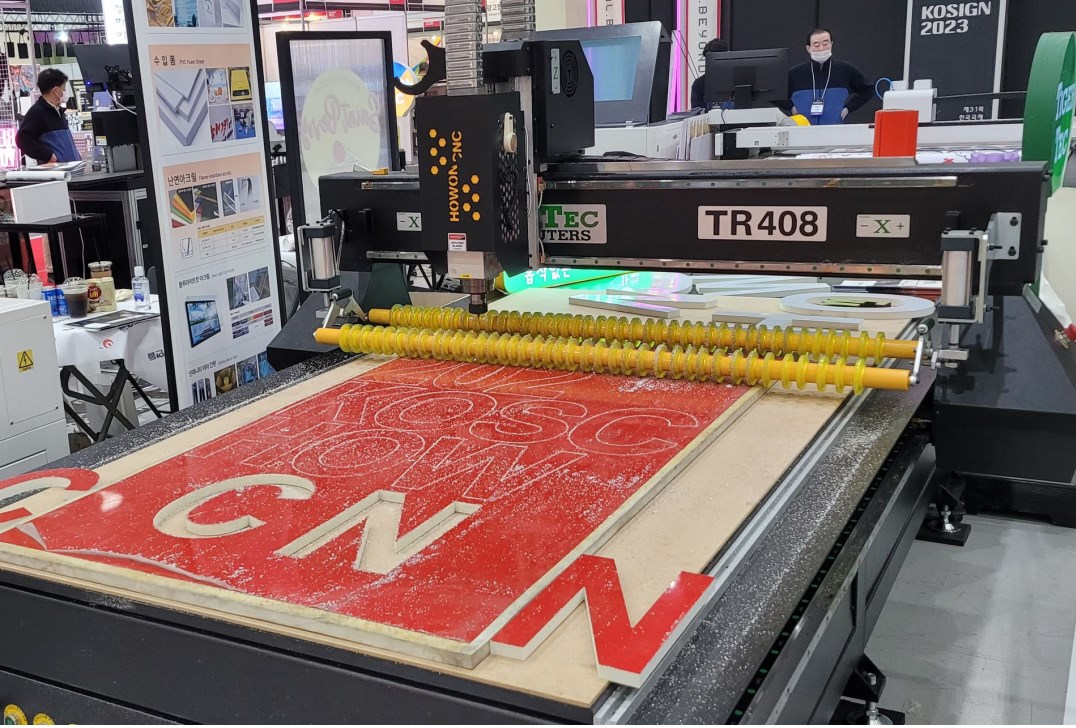

TigerTec TR408 SHOP Series CNC Routers are extremely flexible machines. We designed them for easy configuration to meet high speed routing application requirements. Ideal for Sign Making, Prototyping, Model Making, Engraving, Woodworking, Metal Engraving, Plastics, Foam, Educational Applications and General Fabrication.

Outstanding features:

*1240X2460mm (4'X 8') process area

*Easy to Use Hand-held controller

*With a 3.0KW HSD high frequency spindle

*TigerTec rack pinion and Linear rails on all 3-axes

*Maintenance free brushless stepper drive motors

*T-slot working table with T-clamp for fixing the processing materials

Options:

*6.0KW, 7.0KW Spindle available upon request.

*5'x 10', 7' x 12'stock sizes (Special sizes available upon request)

*Optional PC based system available

*T-slot vacuum working table

*Japan THK linear rail

*Germany WMH Helical rack pinion

*Servo driving system

*Mist cooling system

*Lubricating system

*Dust collector

Vacuum pumps from China or Germany for your choice

Applications:

Ideal for Sign Making, Prototyping, model Making, Engraving, Woodworking, Metal Engraving, Plastics, Foam Educational Applications and General Fabrication. Designed to cut a multitude of materials such as composite materiasl, foam, plastic, solid wood, soft wood, acrylic, MDF, bamboo, PVC, double color board, brassm copper, aluminum and ACP etc.

Model No. | Process Area | Accuracy | Weight | Foot Print | ||||

X | Y | Z | W | L | H | |||

TR408SHOP | 1240mm | 2460mm | 200mm | ± 0.05mm | 1000KGS | 2024mm | 3300mm | 1600mm |

51.2″ | 98.4″ | 7.9″ | 79.7″ | 129.9″ | 63″ | |||

TR510SHOP | 1500mm | 3000mm | 200mm | ± 0.05mm | 1300KGS | 2224mm | 3800mm | 1600mm |

59.0″ | 118.1″ | 7.9″ | 87.6″ | 149.6″ | 63″ | |||

TR710SHOP | 2000mm | 3000mm | 200mm | ± 0.05mm | 1500KGS | 2724mm | 3800mm | 1600mm |

78.7″ | 118.1″ | 7.9″ | 107.2″ | 149.6″ | 63″ | |||

CNC - Nesting machining centre is the new high-performance machining centre for Nesting operations, compact and efficient, with a gantry structure, TigerTec offers top-of-the-range technology and guarantees optimum precision in every machining operation.

EXPLOPE

Hydraulic Bending Machine is a type of sheet metal bending machine, which is suitable for sheet metal plate bending process. The press brake capacity ranges from 40 ton to 400 ton and the table length from 2 meters to 6 meters. Hydraulic Bending Machine belongs to forging machineries. The main role is in the metal processing industry. Then, its products are widely used in light industry, aviation, shipbuilding, metallurgy, instrument, electrical appliances, stainless steel products, steel structure construction and other industries.

EXPLOPE

TigerTec TR408AD ATC is designed for efficient working in speed and reliability.

EXPLOPE

TigerTec Inc is a manufacturer of CNC routers, CNC plasma cutters, CNC laser cutters, CNC assessories, Fiber laser cutting machine and handheld fiber laser welding machine and so on.

Address: #6 Caofan Industrial Park, Zhangqiu Dist. Jinan, Shandong P.R. China E-Mail: info@tigerteccnc.com.cn Phone: +86 13335116636 Tech Support: support@tigerteccnc.com.cn Phone: +86 18560168108

TIGERTEC US

Address: #1406 Lowater R.d, Chippewa Falls, WI 54729, USA

E-Mail: david_slowinski@hotmail.com Phone: +1 (715) 456-1919

Phone: 0086-67800878-8000 Fax: 0086-67800878-8029 info@tigerteccnc.com.cn 【I also want to customize a website】