HSD ATC spindle 9.5KW with air-cooling, ER32, 24000RPM, characterised by extremely high relicability and stability for processing work. Spindle can be rotated 180 degrees to engrave and cut 4D processing work.

The functionality of the control system allows dominance over offsets, file manipulation, process speeds and also tool length and wear compensation.

The yaskawa servo driver is designed to provide you with an excellent performance and high reliability. Small size, easy to carry and store, can be used for a long time. High quality performance: the servo motor is made of high-quality aluminum alloy material, which is durable and has good corrosion resistance. Convenient operation: the servo motor is equipped with a high-speed variable speed sensor, which can be adjusted according to different needs. Perfect for any occasion: this servo motor is suitable for all kinds of weather conditions, such as rainy, snowy, windy, and so on.

Carrousel with 12 automatic tool change facility by Servo motor ( Upgrade available up to 16 or 20 ). faster tool change speed, higher production efficiency.

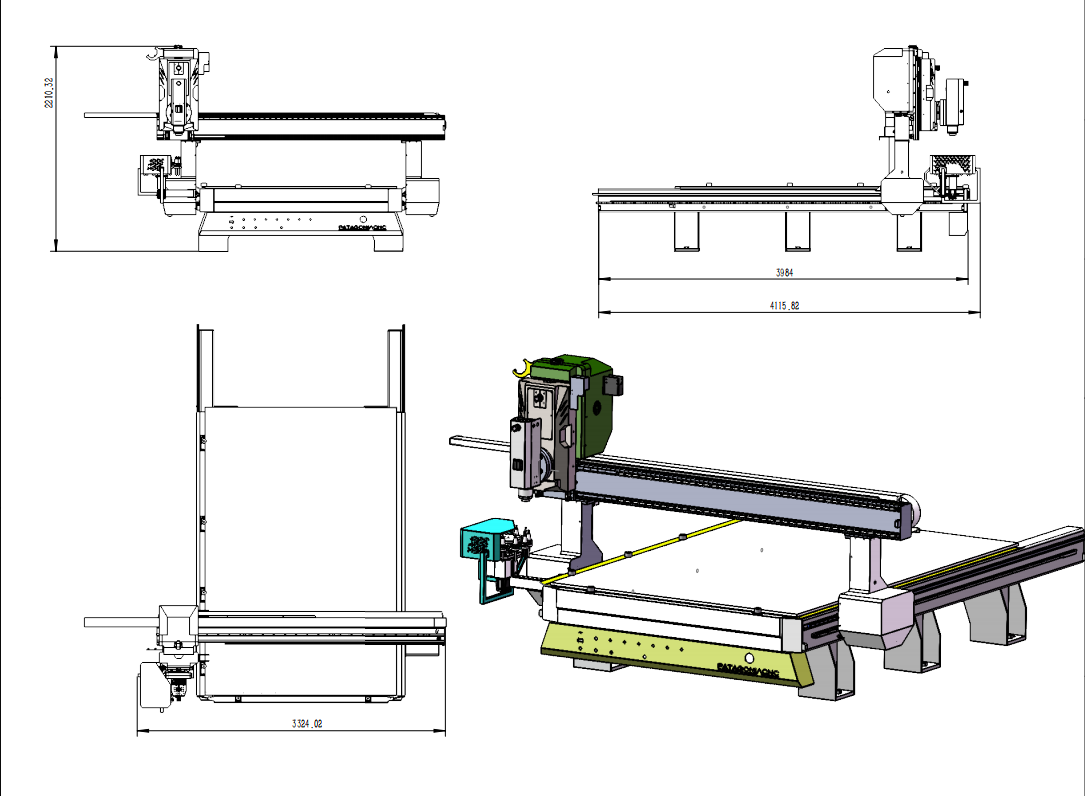

TR408AD-4th axis Spindle can be rotated 180 degrees to engrave and cut for different surface carving, arc-surface milling, bend surface machining for 4D processing work, like special shaped arts, banded doors or cabinets. The 4 Axis CNC router is our newest multi axis CNC router packed full of features offering you a superior experience and control over your projects.

Combined with a world renowned control system made by Syntec, auto tool change and a unique removable pod and rail system - this 4 axis machine gives you both side control as well as your standard 3 axis CNC operation, perfect for processing doors, frames and furniture. With it's a dvanced closed loop servo motors and fast transmission the 4 axis offers you high speed opera on with versatile productivity options.

Outstanding Features:

* Spindle can rotate +/- 90 degree, which can realize side milling, punching, and cutting.

* These four axes can work simultaneously with a real four-axes control system by special program.

* Suitable for processing all kinds of curved surfaces with high precision and fast speed, which fully meets the needs of carving.

Applications:

Widely used in casting molds,foam molds, automotive molds, train molds, aviation molds, ship molds, paraffin molds, and more applications.

Model No. | Process Area | Accuracy | Weight | Foot Print (W*L*H) | ||||

X | Y | Z | ||||||

TR408AD -4th axis | 1240mm | 2460mm | 200mm | ± 0.05mm /m | 1500KGS | 2024mm | 3300mm | 1600mm |

51.2″ | 98.4″ | 7.9″ | 79.7″ | 129.9″ | 63″ | |||

TR510AD-4th axis | 1500mm | 3000mm | 200mm | ± 0.05mm /m | 1800KGS | 2224mm | 3800mm | 1600mm |

59.0″ | 118.1″ | 7.9″ | 87.6″ | 149.6″ | 63″ | |||

TR710AD-4th axis | 2000mm | 3000mm | 200mm | ± 0.05mm /m | 2100KGS | 2724mm | 3800mm | 1600mm |

78.7″ | 118.1″ | 7.9″ | 107.2″ | 149.6″ | 63″ | |||

TR712AD-4th axis | 2000mm | 4000mm | 200mm | ± 0.05mm /m | 2300KGS | 2724mm | 4800mm | 1600mm |

78.7″ | 157.5″ | 7.9″ | 107.2″ | 189″ | 63″ | |||

CNC - Nesting machining centre is the new high-performance machining centre for Nesting operations, compact and efficient, with a gantry structure, TigerTec offers top-of-the-range technology and guarantees optimum precision in every machining operation.

EXPLOPE

Hydraulic Bending Machine is a type of sheet metal bending machine, which is suitable for sheet metal plate bending process. The press brake capacity ranges from 40 ton to 400 ton and the table length from 2 meters to 6 meters. Hydraulic Bending Machine belongs to forging machineries. The main role is in the metal processing industry. Then, its products are widely used in light industry, aviation, shipbuilding, metallurgy, instrument, electrical appliances, stainless steel products, steel structure construction and other industries.

EXPLOPE

TigerTec TR408AD ATC is designed for efficient working in speed and reliability.

EXPLOPE

TigerTec Inc is a manufacturer of CNC routers, CNC plasma cutters, CNC laser cutters, CNC assessories, Fiber laser cutting machine and handheld fiber laser welding machine and so on.

Address: #6 Caofan Industrial Park, Zhangqiu Dist. Jinan, Shandong P.R. China E-Mail: info@tigerteccnc.com.cn Phone: +86 13335116636 Tech Support: support@tigerteccnc.com.cn Phone: +86 18560168108

TIGERTEC US

Address: #1406 Lowater R.d, Chippewa Falls, WI 54729, USA

E-Mail: david_slowinski@hotmail.com Phone: +1 (715) 456-1919

Phone: 0086-67800878-8000 Fax: 0086-67800878-8029 info@tigerteccnc.com.cn 【I also want to customize a website】