Adopt new advantage motion control technique user-friendly interface design, stronger functions, stable for operation with a longer service life. The operation is simple and convenient, and can meet the requirements of 4-axis processing.

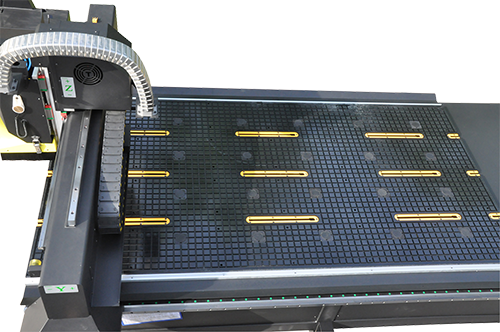

Be easily customized to fit your particular part geometry. Simplest and fastest way to hold down your sheet goods.

Lathe bed, gantry and other big parts of CNC Routers are all milled by our vertical machining center to ensure better accuracy and good finishing.

Diameter of rotary device is 400mm, length can be 2200mm, Not only can 2D processing, but also can realize the processing of 3D materials. One machine for two purposes, very cost-effective. Can meet the needs of more customers.

TR408AD-R with rotary device is one of CNC machines designed and developed for carving industry focusing on cylindrical as well as flat engraving/carving and cutting applications with its 4th axis in place making 3D carving on cylindrical surface on any wood.

Outstanding Features:

* 1240*2460mm (4′x 8′ ) process area.

* Mechanical parts: All mechanical parts made in TigerTec factory by CNC machine tools to ensure we have better quality.

* Electronics: We use all world branded components for TigerTec CNC routers, as: Siemens, Schneider, Igus and Phoenix

* Electronic spindle: We use HSD 3.0KW from Italy which is the top brand in the world.

* Painting: We use sand blasting and powder coating for the machine.

* Massive gantry rides on extremely accurate TigerTec rack and pinion and HIWIN linear guide ways for each of XYZ -movements.

* Powered by Stepper driving system with planetary reducer.

* Work surface constructed bakelite with T-slot tracks ensure plenty of options for holding down materials.

* Side rotary device for Cylinder processings: diameter 400mm, with length 2.2m.

Applications:

Widely applied in 3D Buddha statues, stair columns, sofas, table legs and other cylinder workpieces.

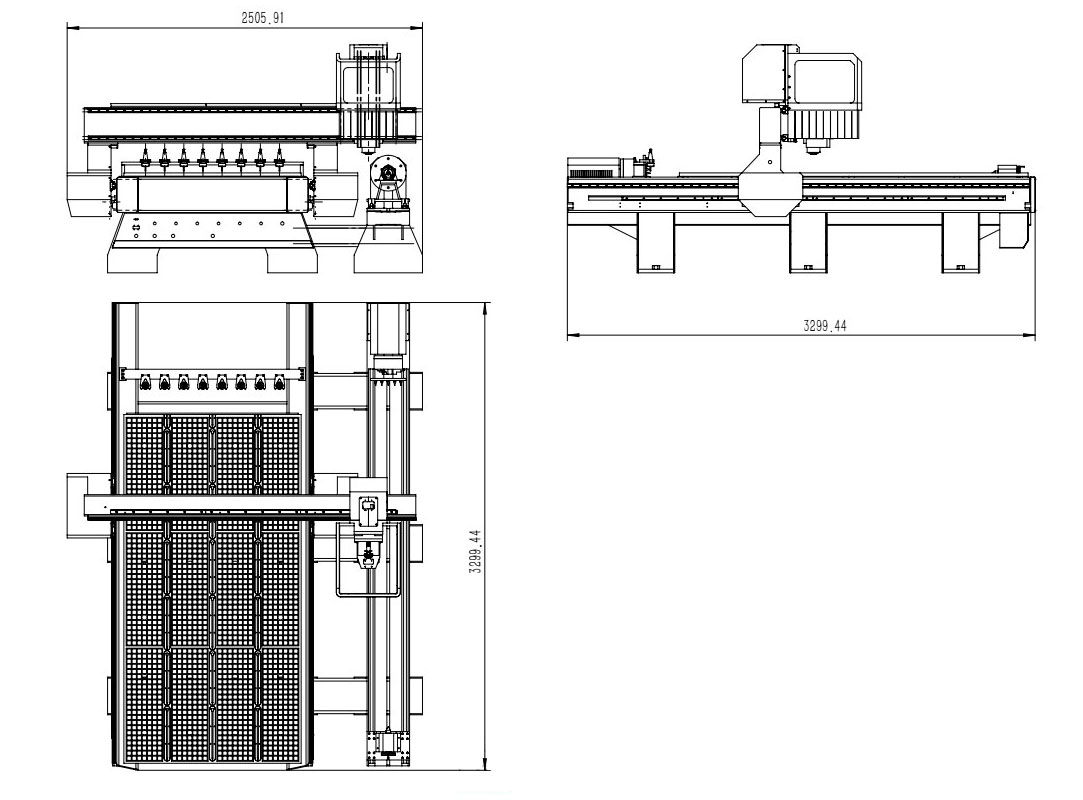

Model No. | Process Area | Accuracy | Weight | Foot Print (W*L*H) | ||||

X | Y | Z | ||||||

TR408AD -R | 1240mm | 2460mm | 200mm | ± 0.05mm /m | 1500KGS | 2024mm | 3300mm | 1600mm |

51.2″ | 98.4″ | 7.9″ | 79.7″ | 129.9″ | 63″ | |||

TR510AD-R | 1500mm | 3000mm | 200mm | ± 0.05mm /m | 1800KGS | 2224mm | 3800mm | 1600mm |

59.0″ | 118.1″ | 7.9″ | 87.6″ | 149.6″ | 63″ | |||

TR710AD-R | 2000mm | 3000mm | 200mm | ± 0.05mm /m | 2100KGS | 2724mm | 3800mm | 1600mm |

78.7″ | 118.1″ | 7.9″ | 107.2″ | 149.6″ | 63″ | |||

TR712AD-R | 2000mm | 4000mm | 200mm | ± 0.05mm /m | 2300KGS | 2724mm | 4800mm | 1600mm |

78.7″ | 157.5″ | 7.9″ | 107.2″ | 189″ | 63″ | |||

CNC - Nesting machining centre is the new high-performance machining centre for Nesting operations, compact and efficient, with a gantry structure, TigerTec offers top-of-the-range technology and guarantees optimum precision in every machining operation.

EXPLOPE

Hydraulic Bending Machine is a type of sheet metal bending machine, which is suitable for sheet metal plate bending process. The press brake capacity ranges from 40 ton to 400 ton and the table length from 2 meters to 6 meters. Hydraulic Bending Machine belongs to forging machineries. The main role is in the metal processing industry. Then, its products are widely used in light industry, aviation, shipbuilding, metallurgy, instrument, electrical appliances, stainless steel products, steel structure construction and other industries.

EXPLOPE

TigerTec TR408AD ATC is designed for efficient working in speed and reliability.

EXPLOPE

TigerTec Inc is a manufacturer of CNC routers, CNC plasma cutters, CNC laser cutters, CNC assessories, Fiber laser cutting machine and handheld fiber laser welding machine and so on.

Address: #6 Caofan Industrial Park, Zhangqiu Dist. Jinan, Shandong P.R. China E-Mail: info@tigerteccnc.com.cn Phone: +86 13335116636 Tech Support: support@tigerteccnc.com.cn Phone: +86 18560168108

TIGERTEC US

Address: #1406 Lowater R.d, Chippewa Falls, WI 54729, USA

E-Mail: david_slowinski@hotmail.com Phone: +1 (715) 456-1919

Phone: 0086-67800878-8000 Fax: 0086-67800878-8029 info@tigerteccnc.com.cn 【I also want to customize a website】